Small manufacturing robots are lightweight and compact. They are portable programmable machines that can perform different tasks. They can also be utilized in various workstation scenarios. Small industrial robots are ideal for companies that wish to incorporate robotics in their operations.

When robotics was first introduced in the world of production, they were cumbersome, bulky, and huge. That is why these robotics were first stored in a set place and only performed a specific function. On the other hand, small robots are programmable to perform many different tasks. They can also be relocated from one section to another depending on a company's needs.

Applications of Small Industrial Robots

More miniature robots have been used in different areas, including:

1. Welding

As opposed to human welders who could only work for about twelve hours each day, industrial robots have the ability of working 24 hours each day. These robots can work this long without getting fatigued nor missing a step. What's more, the quality of welding produced by robots is unmatched in terms of perfection. You will get the same quality you started with for days on end. The resulting product is increased production.

When robotics are used to weld, you will only need one human conducting quality control. As such, you will reduce the number of people whose salaries and insurance you have to pay for. This means saving up more money.

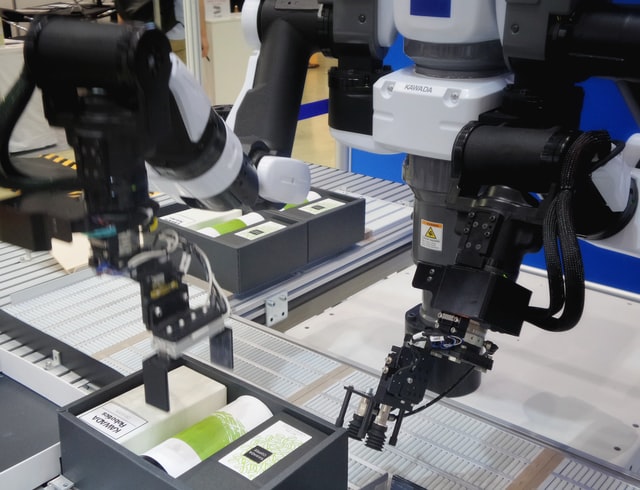

2. Disassembly and assembly

More miniature industrial robots have also been used in the assembly of lightweight products. These robots are programmed and can be fitted with cameras. The cameras will help sort through and also identify the materials needed to assemble products. For example, using a robotic arm increases efficiency, thereby reducing production time. In return, the robots will positively impact your company's ROI.

The robotic arm can also be used in disassembly and to separate waste materials from those recycled and retained. This arm will perform this function in the utmost accurate manner.

3. Painting

Robots have been widely used in the automobile industry more so, in the assembly of vehicles. Now, small industrial robots are also used in this industry in the painting section. They paint car body panels as opposed to painting a wholly assembled vehicle. This improved finish and quality as each panel get to be painted individually, resulting in uniformity.

Other than the automotive industry, you can also use these small robots to paint houses. They can paint floors and walls of buildings. They will give off a more uniform finish and reduce the need for a re-paint, thus reducing paint wastage. This will help you save up on the overall expenditure as well as save on labor.

4. Dropping and picking

Most warehouses also use small robots to drop and pick light items. They help to pick and then drop items from shelves. The only thing you will have to do is feed them with data and program them. After that, items will be arranged in an efficient and orderly manner.

If the warehouse is a delivery one, these small robots can retrieve or store items and, in so doing, deliver faster than humans would. The result is a faster delivery turnaround time.

5. Dangerous chemicals handing

Many different manufacturing industries handle dangerous chemicals. In the past, they were managed by humans. This resulted in many fatal accidents caused by hazardous handling. Nowadays, such chemicals are only handled by small robots. This has seen a reduction in chemical accidents because robots will take the chemicals with the care and meticulousness required.

Buying a small industrial robot

Technology is now going more diminutive in size, and this can be seen even in the telecommunications industry. That is why other sectors are following suit and preferring to purchase small industrial robots. The good news is there is always a small robot that can perform any task you may have.

Even so, it would be best if you were as specific as can be when choosing a small robot. The following factors should be put into consideration when it comes to choosing a small robot:

-

Work cell: your industry's infrastructure should be built in a way that accommodates small robots. You can check robot integrators and have them assess your company's needs, and then offer a tailor-made automation plan.

-

Intelligence: Small robots are also highly intelligent and can thus complete even the most complex tasks without compromising quality.

-

Adaptability: Bots aren't used so that they can replace humans. They can work collaboratively with humans when equipped with spatial cognizance.

Some small industrial robots for consideration

One of the key benefits of using small robots is their movable body which can make the same motions as humans. These small robots have been created with expressive movements to have more robots in many other contexts.

There are many different small robots out there. That is why you should have good knowledge of what functions you want the robot to perform. You should also have a good understanding of each type of small robot available before purchasing one. Examples of small industrial robots are:

-

Dual-arm: These robots are used in industries to perform operations that require two hands. Their programming approach is offline and online methods.

-

Cartesian: This robot utilizes linear slides. It streamlines robotic control and coordinates motion.

-

Robotic arm: This is a mechanical arm that is identical to a human arm. It is available for orientation and positioning. They are highly used in complex applications that require delicate movements. This arm can be equipped with many effectors that are suitable for specific applications.

Conclusion

When looking for small robots to use in your production line, picking the right one is very important. Identify if the job needs bigger robots or can use a smaller one. Keep in mind small robots guarantee reach and stability. Bigger robots are not easy to manipulate and position in places with limited space hence the need to use small robots. As such, these precise and compact machines are necessary whenever you think of manufacturing and assembly.