Space agencies have been looking into ways of creating infrastructures in space, but the limited supply and unsustainable transportation methods make it difficult. Researchers are already exploring alternatives and found that 3D printing might be a suitable solution.

3D Printing in Space

Anything that has to do with building is more difficult in space considering that Earth's gravity is different and resources will have to be transported. It's not exactly cheap or easy to make several space trips just for supplies.

Given the situation, both researchers and space agencies have been looking into ways that serve as a more sustainable and self-sufficient alternative. The conclusion led to 3D printing as it enables in-demand production and reduces the need to transport ready-made materials.

While this is a significant find, there are still a couple of kinks to iron out before it can be done. 3D printers are built to function on Earth, so they will have to be reconfigured to be able to print materials out in space, as reported by Interesting Engineering.

Gravity serves as a factor when it comes to ejecting the material out of the 3D printer's nozzle, along with the way it is laid out onto a substrate. The filament's shape when printed on Earth is different from when it is printed in microgravity.

"By changing additional variables in the printing process, such as writing speed and extrusion pressure, we're able to paint a clearer image of how all these parameters interact to tune the shape of the filament," says West Virginia University doctoral student Jacob Cordonier.

The researchers are experimenting with a specific material called titania foam. It was mentioned that the Moon also contains minerals to titanium oxide. As such, lunar astronauts may be able to take resources from the Moon instead of Earth and use them for 3D printing equipment they need.

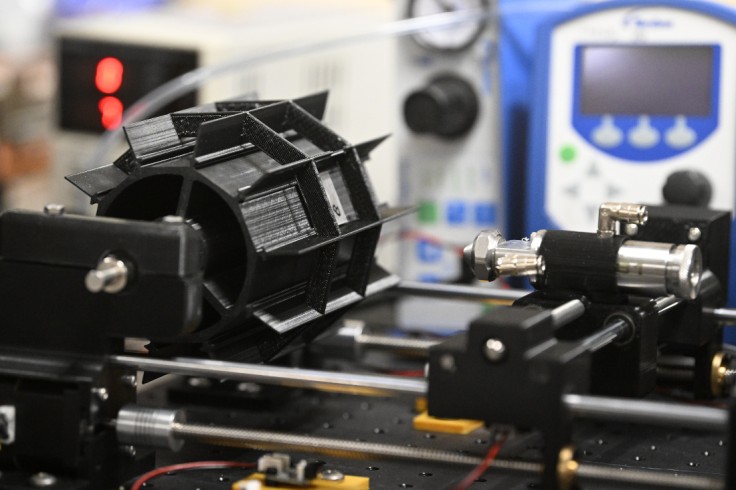

They even designed a 3D printer that's specifically meant to work better in microgravity. Using titanium dioxide foam, researchers are conducting experiments to see how it fares. It also comes with certain uses other than being an accessible resource in space.

Titania foam can also be used for various applications such as UV blocking or water purification. If all goes well, the specialized 3D printer might be sent to the International Space Station for further observation of its potential.

Aligns with Plans to Create Buildings on the Moon

The research may contribute to NASA's plans to build a house on the moon. The space agency intends for it to be built by 2040, and not only will it be for astronauts, but for the general public who has the means to fly to the moon as well.

The US Space Agency has already granted a construction firm $60 million for this project, with strategies that also involve using 3D printing technology. Resources that will be used include lunar concrete, composed of rocks and moon dust, as per Earth.com.

It will be in collaboration with ICON, an Austin-based company that already has experience with 3D printing structures with the use of Earth resources like cement, sand, and water as filaments. It can create structures that can later be assembled.